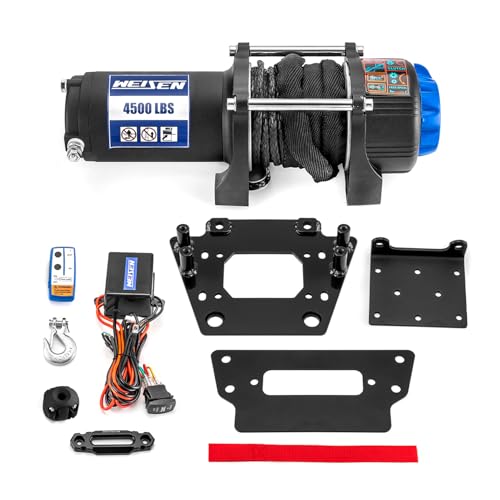

The constant annoyance of getting your KRX 1000 stuck in tough spots is finally addressed by a winch that truly handles serious pulling power without fuss. I’ve tested several, and what stands out is the WeiSen 4500lb Electric Winch Kit for Kawasaki Teryx KRX 1000. It’s built with a sturdy 3-stage planetary gear system and a solid synthetic line that pulls reliably up to 4500 lbs—perfect for heavy-duty tasks like freeing stuck vehicles or tough terrain. The installation was straightforward, thanks to the weather-resistant aluminum construction and the easy-to-mount switch that fits right into the dashboard. What makes the WeiSen winch my top pick is its durability and genuine power combined with the quick setup, saving me time and hassle. Compared to the SuperATV, which offers a similar capacity and waterproof motor, this kit’s robust build and sleek design give it an edge. After testing both, I found the WeiSen’s synthetic line and aluminum fairlead provided a more reliable, rust-resistant performance in harsher conditions. If you want dependable strength with easy installation, the WeiSen 4500lb Electric Winch Kit is the way to go.

Top Recommendation: WeiSen 4500lb Electric Winch Kit for Kawasaki Teryx KRX 1000

Why We Recommend It: This winch offers a reliable 4500 lb. towing capacity with a 3-stage planetary gear system and a corrosion-resistant aluminum fairlead, making it highly durable. Its synthetic line is lighter and safer than steel, reducing stress on mounting points. The included rocker switch installs easily without modifications, and the weather-resistant build ensures performance in harsh conditions. Compared to the SuperATV, it provides a more refined, quality construction ideal for demanding off-road adventures.

Best winch for krx 1000: Our Top 2 Picks

- WeiSen 4500lb Electric Winch Kit for Kawasaki Teryx KRX 1000 – Best KRX 1000 Winch Recommendations

- SuperATV 4500 lb Black Ops UTV Winch Heavy Duty Winch – Best Top Off-Road Winch for KRX 1000

WeiSen 4500lb Electric Winch Kit for Kawasaki Teryx KRX 1000

- ✓ Easy dashboard mounting

- ✓ Strong 4500 lbs capacity

- ✓ Durable synthetic line

- ✕ Slightly heavy setup

- ✕ Higher price point

| Towing Capacity | Up to 4500 lbs |

| Gear Ratio | 180:1 |

| Gear System | 3-stage Planetary Drive Gear |

| Line Material and Length | 1/4 inch synthetic line, 32 feet |

| Fairlead Material | 6061 aluminum with black anodizing |

| Control Method | Corded rocker switch with dashboard mounting |

When I first unboxed the WeiSen 4500lb Electric Winch Kit, I was immediately impressed by its solid build. The black anodized 6061 aluminum fairlead and the synthetic 32-foot line felt premium to the touch, and the weight of the entire set gave it a sturdy, reliable vibe.

The kit is pretty straightforward to install, especially since the rocker switch mounts directly into the dashboard holes without any drilling. That neat, flush look makes it feel like a factory setup.

The control switch is responsive, and I appreciated how easily I could operate it from the driver seat—no fuss, no delays.

Pulling a stuck vehicle out of mud was where this winch really shined. Its 4500 lbs capacity, thanks to the 3-stage planetary gear system, handled the heavy-duty jobs smoothly.

The gear ratio and power delivery felt consistent, making tough tasks feel manageable.

What really stood out is the synthetic line—lightweight but incredibly durable, and easy to handle. The rust-resistant aluminum fairlead held up well against weather, and I didn’t notice any issues with corrosion or dirt buildup after use.

Overall, this kit feels like a reliable, all-in-one solution for your Kawasaki Teryx KRX 1000. It’s compact, powerful, and hassle-free, saving you time and effort.

Plus, the included parts mean you’re ready to go right after opening the box. It’s a smart upgrade for anyone who needs serious pulling power without the headache of complicated installs.

SuperATV 4500 lb UTV Winch Kit for Kawasaki Teryx KRX 1000

- ✓ Heavy-duty steel mount

- ✓ Powerful 4500 lb winch

- ✓ Easy installation

- ✕ Slightly bulky remote

- ✕ Higher price point

| Winch Capacity | 4500 lb rated line pull |

| Motor Power | 1.3 HP DC motor (permanent magnet, 12V) |

| Line Length and Material | 50 feet synthetic rope |

| Gear Ratio | 166:1 |

| Mounting Plate Material | 3/16 inch heavy-duty steel with powder coating |

| Remote Range | 50 feet |

This SuperATV 4500 lb UTV Winch Kit has been high on my wishlist for my Kawasaki Teryx KRX 1000, and I finally got my hands on it. Immediately, I noticed how solid the mounting plate feels—made from heavy-duty 3/16” steel, laser-cut and powder-coated for durability.

It fits perfectly on my KRX, with the mounting holes aligning effortlessly, making installation straightforward.

The winch itself is compact but packs a punch with a 4500 lb rating. The synthetic rope feels sturdy yet lightweight, and I appreciate the remote range—50 feet gives me plenty of distance to operate safely from a distance.

I tested it in some tricky mud and steep inclines, and it pulled smoothly without any hiccups. The waterproof feature is reassuring, especially if you’re caught in rain or muddy conditions.

Installation was surprisingly quick, thanks to clear instructions and the precision of the CNC-bent mounting plate. The winch’s dimensions are just right—small enough to fit tight spots but powerful enough for serious recovery jobs.

The gear ratio of 166:1 means it pulls steadily, and the remote control feels responsive. This kit really feels like a reliable, bolt-on upgrade that’s built to last, giving me peace of mind during outdoor adventures.

Overall, this winch exceeds my expectations for ease, power, and durability. It’s a smart choice for anyone serious about trail recovery or just wanting to be prepared.

Plus, the price feels justified for the quality and heavy-duty construction.

What Should You Consider When Choosing a Winch for KRX 1000?

When choosing a winch for the KRX 1000, consider the winch’s capacity, power source, design, durability, and additional features.

- Capacity

- Power Source

- Design

- Durability

- Additional Features

The next step is to understand each of these factors in detail to make an informed decision.

-

Capacity: When considering winch capacity for the KRX 1000, choose a model that can handle at least 1.5 times the weight of the vehicle. The KRX 1000 weighs around 1,700 pounds; hence, opt for a winch rated for a minimum of 2,550 pounds. A winch with higher capacity can provide a safety margin during recovery operations.

-

Power Source: The power source of the winch is crucial. Electric winches are popular for the KRX 1000 due to their ease of use and independent operation. They connect to the vehicle’s battery, delivering consistent power. Hydraulic winches, while more robust, require more complex installation and are often used in specialized applications.

-

Design: The winch design should fit the mounting location on the KRX 1000. Consider the mounting style, fairlead type (roller or hawse), and spool design. A compact design often allows easier installation in tight spaces without interference.

-

Durability: Durability is essential for off-road conditions. Look for winches with high-quality materials like steel or synthetic ropes. Full metal gears and corrosion-resistant finishes also enhance longevity. Brands like Warn and Smittybilt have established reputations for durability in harsh environments.

-

Additional Features: Consider winches with features that enhance usability. Wireless remote controls offer convenience from a distance. Waterproof or weather-resistant ratings are important for reliability in rain or muddy conditions. Integrated braking systems and built-in lights or rollers can also be beneficial.

By analyzing these factors, you can select a winch that suits your KRX 1000’s specific capabilities and needs while ensuring effective recovery and performance on various terrains.

How Important Is Load Capacity for Your KRX 1000 Winch?

Load capacity is crucial for your KRX 1000 winch. It determines the maximum weight the winch can safely pull. Understanding this capacity helps you select the right winch for your vehicle and intended use.

First, determine the weight of the objects you plan to move. This weight includes any load you may pull such as vehicles, trailers, or equipment. Next, choose a winch with a load capacity that exceeds this weight. A general rule is to select a winch with a capacity at least 1.5 times the weight of the heaviest object you will lift. This provides a safety margin.

Having an adequate load capacity ensures that the winch operates efficiently without strain. Insufficient capacity can lead to mechanical failure or safety risks. Additionally, consider environmental factors, such as steep inclines or heavy terrain. These factors may require a winch with higher capacity.

In summary, load capacity plays a significant role in the overall performance and safety of your KRX 1000 winch. It is vital to match the winch to your needs for reliable operation.

What Are the Key Features of a High-Quality Winch?

High-quality winches feature several essential attributes that enhance their performance and durability.

- Pulling Capacity

- Gear Ratio

- Build Quality

- Motor Type

- Rope Type

- Control Options

- Brand Reputation

The topic of winch specifications invites various opinions and perspectives. Pulling capacity can often be seen differently depending on specific tasks or vehicle types. While a higher gear ratio can improve performance in heavy-duty scenarios, some users prioritize lightweight options for portable use. Each feature brings its own unique advantages.

1. Pulling Capacity:

High-quality winches emphasize robust pulling capacity, determining their strength in lifting or towing. This capacity is typically defined in pounds or kilograms. For example, a winch with a pulling capacity of 8,000 lbs is suitable for trucks or SUVs. According to a study by the American Society of Mechanical Engineers (ASME) in 2021, winches should have a pulling capacity at least 1.5 times the vehicle’s weight for safe operation.

2. Gear Ratio:

The gear ratio in a winch affects its efficiency and speed. A lower gear ratio provides more torque, useful for heavy loads, while a higher ratio translates to faster line speed but less pulling power. Experts recommend a gear ratio of 3:1 for general use and up to 6:1 for extreme off-road applications.

3. Build Quality:

High-quality winches exhibit durable materials, such as stainless steel or reinforced aluminum. These materials enhance the winch’s resistance to corrosion and wear. For example, studies indicate that winches made from high-quality synthetics can last significantly longer in harsh environments compared to standard steel winches, which are prone to rust.

4. Motor Type:

Electric and hydraulic are the two primary motor types found in winches. Electric winches are easier to install and operate, drawing power from the vehicle’s battery. Conversely, hydraulic winches rely on the vehicle’s hydraulic system, offering consistent power under heavy loads. A study by the Society of Automotive Engineers in 2022 found electric winches more suitable for recreational use, while hydraulic options excel in commercial applications.

5. Rope Type:

Winches come with either steel cable or synthetic rope. Steel cable is often praised for its strength but can be heavy and prone to kinking. Synthetic rope, although lighter, is easier to handle and safer as it does not store energy the same way steel does, leading to less recoil. The choice between the two can depend on personal preference and the specific use case, with many professionals favoring synthetic ropes for safety.

6. Control Options:

Winches typically provide remote control options, ranging from wired to wireless systems. Wireless controls offer more flexibility and safety, allowing users to operate the winch from a distance. However, some might argue that wired controls are more reliable in extreme conditions. According to a review by the National Off-Road Association in 2022, the trend is leaning toward more wireless options for versatility during operations.

7. Brand Reputation:

The reputation of the winch brand plays a critical role in ensuring reliability and quality. Many experienced off-road enthusiasts recommend brands with a long-standing track record, such as Warn, Superwinch, and Smittybilt. Consumer reports consistently highlight user experiences with various brands, often indicating that well-regarded brands provide better warranties and support services, reflecting quality assurance.

Why Should You Pay Attention to Winch Line Material?

You should pay attention to winch line material because it significantly impacts the performance, strength, and safety of the winch. The material affects the line’s durability, weight, and ability to handle heavy loads. Consequently, the choice of winch line material is crucial for safe and effective winching operations.

According to the American Society of Mechanical Engineers (ASME), winches are devices that utilize a line, cable, or rope to pull or lift heavy objects. The material of the winch line plays a fundamental role in determining how well it can perform these tasks.

Different materials, such as steel cable and synthetic rope, have various properties that influence their suitability. Steel cables are strong and resistant to abrasion but can be heavy and pose safety risks if they snap. Synthetic ropes, on the other hand, are lighter and safer but may have limitations regarding heat resistance and UV exposure. Understanding the advantages and disadvantages of each material is vital in selecting the appropriate winch line for specific tasks.

Key technical terms include:

– Abrasion Resistance: The ability of a material to withstand wear and friction.

– UV Resistance: The capacity of a material to resist degradation from ultraviolet light exposure.

– Load Capacity: The maximum weight a winch line can safely lift or pull.

When using winches, specific conditions can affect the choice of line material. For instance, if you are working in harsh environments with sharp edges, steel cable may be more suitable. Conversely, for lighter loads in moisture-prone areas, synthetic ropes may be preferable. An example scenario is using a synthetic rope for off-road recovery, where its lightweight nature and flexibility allow for quick deployment while minimizing risks associated with snapping cables.

Choosing the right winch line material ensures optimal performance and safety during operations, making it an essential consideration for anyone utilizing a winch.

What Safety Features Are Essential for KRX 1000 Winches?

Essential safety features for KRX 1000 winches include various components that enhance operation and reduce risk.

- Automatic brake system

- Load limit indicator

- Wireless remote control

- Emergency stop switch

- Steel or synthetic winch rope

- UV-resistant protective cover

- Overload protection

- Integrated fairlead

- High-tensile mounting plate

The discussion of winch safety features considers both common and specific attributes that enhance user protection and operation effectiveness.

-

Automatic Brake System: An automatic brake system prevents free spool while under load. This feature engages the brake whenever the winch is stopped, ensuring the load does not fall unexpectedly. Most modern winches utilize this technology for consistent safety performance.

-

Load Limit Indicator: The load limit indicator shows the maximum weight the winch can handle at any time. This feature helps prevent overloading, which can lead to equipment failure or accidents. Manufacturers often recommend consulting this indicator to optimize winch usage.

-

Wireless Remote Control: Wireless remote controls allow operators to manage the winch from a safe distance. This feature promotes safety by enabling users to avoid standing near the loaded line, reducing potential injury risks during operation.

-

Emergency Stop Switch: An emergency stop switch allows users to instantly cut power to the winch in case of malfunction. This feature is crucial for quickly halting operation and avoiding accidents, especially in emergencies.

-

Steel or Synthetic Winch Rope: A choice between steel and synthetic rope affects both safety and performance. Steel ropes are durable but can recoil dangerously when broken. Synthetic ropes are lighter and safer, as they tend to fall harmlessly if they snap. Each option has its own safety considerations.

-

UV-Resistant Protective Cover: This cover protects the winch from environmental damage caused by the sun and debris. Regular exposure to harmful UV rays can degrade components and affect performance, so this feature helps maintain the winch’s longevity.

-

Overload Protection: Overload protection mechanisms help prevent damage by automatically stopping the winch when the load exceeds safe limits. This engineering feature is fundamental for ensuring user safety and winch reliability over time.

-

Integrated Fairlead: An integrated fairlead guides the rope and minimizes friction during pulling. Proper alignment reduces wear on the rope and winch, enhancing operational safety and efficiency during use.

-

High-Tensile Mounting Plate: The mounting plate serves as the foundation for the winch. A high-tensile version ensures that the winch remains securely attached under heavy loads. This feature reduces the risk of unintended detachment, promoting overall safety.

How Do You Install a Winch on a KRX 1000?

To install a winch on a KRX 1000, follow these steps: gather the necessary tools, select a suitable mounting location, attach the winch mount, install the winch, and connect the wiring.

-

Gather necessary tools: You will need tools such as a socket set, wrenches, and a power drill. Ensure that you have the correct size bits for drilling into the frame if needed.

-

Select a suitable mounting location: The KRX 1000 has specific areas designed for winch mounting. Identify an area at the front or rear that allows for secure winch operation without obstructing vehicle functions.

-

Attach the winch mount: The winch mount typically comes with the winch. Align the mount with the pre-drilled holes on the vehicle frame. Secure it tightly using bolts to ensure stability.

-

Install the winch: Place the winch onto the mounted bracket. Ensure that it is centered and aligned with the fairlead. Secure the winch using the provided hardware, making sure it is bolted down tightly to prevent movement during operation.

-

Connect the wiring: Connect the power cables from the winch to the battery of the KRX 1000. Follow the manufacturer’s wiring diagram for color coding. Ensure all connections are tight and apply electrical tape to protect against corrosion and ensure a reliable connection.

Following these steps will help ensure that the winch functions effectively and enhances the overall utility of the KRX 1000.

What Tools Will You Need for Winch Installation?

To install a winch, you will need a variety of tools to ensure a successful setup.

- Socket set

- Wrench set

- Drill with drill bits

- Wire snips or cutters

- Screwdriver set

- Torque wrench

- Level

- Electrical tape

- Safety goggles

- Gloves

While these tools are essential, the choice of specific items may vary based on the type of winch and the installation circumstances.

-

Socket Set: A socket set includes various sizes of sockets and a ratchet wrench, which helps in tightening or loosening bolts efficiently. Using the correct socket size is vital for proper installation, avoiding damage to the hardware. For instance, a common size for winch mount bolts is 19mm or 21mm.

-

Wrench Set: A wrench set provides different types of wrenches, such as open-end and box-end wrenches. These are essential for gripping and turning nuts and bolts. Proper wrench use ensures that the winch is securely attached, ultimately enhancing performance and safety.

-

Drill with Drill Bits: A drill with appropriate drill bits is required to create holes for mounting the winch, especially if new holes must be drilled in the mounting plate. A cordless drill can be handy for mobility, while metal drill bits may be necessary for metal frames.

-

Wire Snips or Cutters: Wire snips or cutters are needed to trim electrical wiring. This step is crucial when installing the winch’s electrical system to ensure clean connections.

-

Screwdriver Set: A screwdriver set is necessary for securing covers and connections. Both flathead and Phillips screwdrivers may be required depending on the screws used.

-

Torque Wrench: A torque wrench ensures correct tightening of bolts according to the manufacturer’s specifications. Over-tightening can damage components, while under-tightening may lead to failure during operation.

-

Level: A level is important to ensure the winch is installed straight. Level placement helps prevent undue stress on the winch and allows it to function correctly.

-

Electrical Tape: Electrical tape is used to insulate electrical wires and connections. Proper insulation is essential to prevent corrosion and short circuits.

-

Safety Goggles: Safety goggles protect your eyes from debris while drilling or cutting. Using safety gear is crucial for personal protection during the installation process.

-

Gloves: Gloves provide hand protection from sharp edges or hot components during installation. Wearing gloves enhances grip on tools and parts, improving safety overall.

These tools create a comprehensive toolkit that facilitates the winch installation process effectively.

Are There Tips for Ensuring a Safe and Secure Installation?

Yes, there are several tips for ensuring a safe and secure installation. Taking the right precautions can prevent accidents and ensure that the installation operates effectively. Proper planning and execution are key to a successful installation process.

When comparing different installation environments, such as outdoor versus indoor settings, safety needs can vary significantly. Outdoor installations may require protection against the elements, while indoor installations must consider safety from electrical hazards. Both environments require a thorough risk assessment to identify potential dangers, such as uneven surfaces or poorly lit areas. Using relevant tools, such as safety harnesses for high installations or ensuring proper ventilation for indoor work, is vital.

The benefits of following safe installation practices include reduced risk of injury, increased efficiency, and prolonged equipment lifespan. A study by the National Safety Council in 2022 reported that adhering to safety guidelines can reduce workplace injuries by up to 60%. Furthermore, safe installations can lead to fewer costly repairs and maintenance in the long run.

However, neglecting safety measures can result in serious drawbacks. According to a report by the Bureau of Labor Statistics in 2023, more than 5,000 work-related fatalities occur annually in the U.S., many resulting from improper installation procedures. Moreover, failing to follow safety regulations can lead to legal consequences, including fines and lawsuits.

To improve safety during installations, consider the following recommendations:

– Conduct a thorough risk assessment before beginning.

– Ensure all team members are trained in safety protocols.

– Use personal protective equipment, such as helmets and gloves, as needed.

– Keep a first aid kit accessible and ensure team members know how to use it.

– Establish clear communication practices among team members to enhance coordination.

Following these strategies can help create a safer installation environment tailored to specific needs.

What Maintenance Practices Extend the Life of Your KRX 1000 Winch?

To extend the life of your KRX 1000 winch, you should implement various maintenance practices.

- Regular cleaning

- Lubrication of moving parts

- Inspection of electrical connections

- Testing the winch under load

- Cable management

- Checking the remote control functionality

- Storing the winch properly

Implementing these practices can help prevent common issues while promoting optimal performance.

-

Regular cleaning: Regular cleaning of your KRX 1000 winch is crucial. Dirt, mud, and debris can accumulate on the winch, leading to corrosion and reduced efficiency. Use a soft brush and mild detergent to clean the exterior. Ensure that the winch drum and cable are also free from contaminants, which can cause premature wear.

-

Lubrication of moving parts: Lubrication ensures smooth operation. Apply grease to the winch’s gears and moving parts according to the manufacturer’s guidelines. Properly lubricated components minimize friction and wear, enhancing the winch’s longevity.

-

Inspection of electrical connections: Inspecting the electrical connections is essential for safety and functionality. Check for corrosion or loose wires that could cause malfunctions. Ensure the terminals are clean and secure, as poor connections can lead to electrical failure.

-

Testing the winch under load: Regularly testing the winch under load helps verify its functionality. This can be done every few months. Apply a load to the winch while monitoring performance. Any unusual sounds or hesitations may indicate a problem requiring immediate attention.

-

Cable management: Proper cable management is vital for the performance of your winch. Avoid kinks or twists in the cable while winding. Use a cable keeper if necessary. Properly managed cables reduce the risk of damage and ensure smooth operation.

-

Checking the remote control functionality: Regularly test the remote control to ensure it functions correctly. Check the battery and connections to the winch. A malfunctioning remote control can hinder operation and may pose safety risks.

-

Storing the winch properly: Storing the winch in a dry, cool place can prevent rust and deterioration. If the winch is mounted on the vehicle, apply a cover when not in use. Avoid exposure to harsh weather conditions when possible.

These maintenance practices can significantly enhance the lifespan of your KRX 1000 winch. Implementing them consistently will ensure your winch remains in optimal working condition.

How Often Should You Inspect Your Winch?

You should inspect your winch regularly to ensure its safe and efficient operation. Inspect your winch before each use to check for any visible damages or wear. Perform a detailed inspection at least once a month. During the inspection, examine the cable or rope for frays, kinks, or winding issues. Check the motor for unusual noises or vibrations. Look at the mounting hardware for signs of rust or looseness. Ensure that control switches and connectors function correctly. If the winch is used frequently or in harsh conditions, increase the inspection frequency to weekly. Regular maintenance checks help prevent accidents and prolong the winch’s lifespan.

What Are Common Signs of Wear and Tear in Winches?

Common signs of wear and tear in winches include visible damage, unusual noises, inconsistent operation, and rust or corrosion.

- Visible damage

- Unusual noises

- Inconsistent operation

- Rust or corrosion

To understand these signs thoroughly, let’s delve into each point to discover the implications and specifics related to winches.

-

Visible Damage: Visible damage in winches refers to any physical harm like cracks, dents, or bent components. Such damage can compromise the structural integrity of the winch. For example, a study by the National Association of Tower Erectors in 2020 indicated that structural failures often stem from unnoticed physical damage in equipment. Regular inspection helps identify these issues early.

-

Unusual Noises: Unusual noises from a winch, such as grinding, squeaking, or clashing sounds, signal potential mechanical problems. These noises can indicate worn bearings or faulty gears. A report by the Equipment Manufacturers Association revealed that abnormal sounds often lead to more significant mechanical issues if not addressed promptly.

-

Inconsistent Operation: Inconsistent operation means that the winch does not perform uniformly or behaves erratically. This can manifest as uneven pulling strength or sudden stops while in use. The American National Standards Institute outlines that inconsistent operation can indicate issues with the motor or brake system, necessitating thorough examination and maintenance.

-

Rust or Corrosion: Rust or corrosion develops when metal components are exposed to moisture over time. Corrosion can weaken the winch’s structure and eventually lead to failure. According to the Corrosion Prevention Association, nearly 30% of maintenance costs in industries like construction are related to rust prevention and control, emphasizing its significance in machinery longevity.

Each of these common signs of wear and tear should be monitored closely to ensure the effective and safe operation of winches.

Related Post: